- Wago Products

- Cabur Products

-

Cembre Products

-

Tube terminals - End sleeves

-

Ring - Fork - Pin - Blade terminals

-

Slide cable lug

-

Tube connectors

-

Copper tube crimp lugs

-

Copper single-hole terminal lug for circuit beakers

-

Crimping through/sleeve connectors

-

Aluminum tube crimp lugs

-

Bimetallic tube crimp lugs

-

Terminals in roll

-

Connections for for railway applications

-

Other products Cembre

-

Tube terminals - End sleeves

- Identification and labeling systems

-

Controls

- Pushbuttons - Selectors - Pilot lights

- Limit switches

- Timers

- Counters - Tachometers

- Digital meters-PID Control-Transducer-Converters

-

Monitoring relays

-

1-ph AC/DC voltage monitoring

-

Speed monitor relay

-

3-ph voltage monitoring

-

1-ph current monitoring

-

3-ph current monitoring

-

3-ph monitoring, phase loss-sequence, asymmetry etc

-

Frequency monitoring

-

Power monitoring

-

Power factor monitoring

-

Level control

-

Dry running and pump alternating

-

Motor temperature monitoring

-

Motor monitoring and potection units

-

Temperature - Humidity - CO2

-

Wind

-

1-ph AC/DC voltage monitoring

- Current transformers

-

Earth leakage control

-

Flush mounting earth leakage controllers

-

Internal mounting earth leakage controllers

-

DIN rail mounting earth leakage controllers

-

Earth leakage controllers with incorporated CT

-

Solid-core toroidal current transformers

-

Split-core toroidal current transformers

-

External multiplier for earth leakage controllers

-

Flush mounting earth leakage controllers

- Switching power supplies and Automatic battery chargers

- Surge protection devices

- PLC - Operator panels - Automation units

- Safety modules

-

Automatic transfer switches controllers

- Engine and generator controllers

- Software and applications

-

Sensors

- Temperature

-

Humidity

-

Pressure transmitters

-

Inductive

-

AC - cylindrical - 2 wires

-

AC - DC - AC/DC - rectangular

-

DC - cylindrical - 2 wires

-

DC - cylindrical - 3 wires

-

DC - for cleaning processes with high pressure and temperature - Ecolab

-

DC - for high temperature

-

Special applications (metal face, analog e.t.c.)

-

Namur and amplifiers

-

Presence and direction of vehicles

-

AC - cylindrical - 2 wires

- Magnetic

- Capacitive

-

Photoelectric

-

Diffuse reflective

-

Diffuse reflective Background suppression

-

Retro-reflective

-

Retro-reflective, Polarized

-

For transparent objects

-

Through-beam

-

Through-beam controllers and sensors

-

Color contrast and color points

-

LASER (narrow beam)

-

Fork Sensor

-

Domestic garage door & Industrial gates control

-

Non conductive liquid level sensor

-

Fibre Optic

-

Diffuse reflective

- Ultrasonic

- Connectors and Cable Plugs

- Level control

- Loop detectors

- Environmental (exterior use)

- Air quality (interior use)

-

Motion - Presence detector - Radar

-

Switches

- Plug-in industrial relays

-

Power and auxiliary contactors - Thermal overload relays

- Motor protection circuit breakers

-

Solid state relays

-

Single phase, small dimensions

-

1 pole solid state relays without built in heatsink

-

1 pole solid state relays with built in heatsink

-

With 2 or 3 independent or not switching poles

-

For DC loads

-

With soft start and analog functions

-

Special functions: sensing, communication, protection

-

3 pole solid state relays with built in heatsink

-

3 phases solid state relays without built in heatsink

-

Electronic contactors and reversing contactors

-

Hybrid single and 3-phase solid state relays

-

Heatsink and accessories

-

Single phase, small dimensions

- Soft starters

- Frequency drivers / inverters

-

Motor control and protection Units

- Switch disconnectors and Rotary cam switches

- Miniature circuit breakers - Fuse holders - Residual current operated circuit breakers

-

Automatic transfer switches

- Energy management

-

Installation and Marine products

- Industrial Plugs and sockets

- Interlocked socket outlets

- Enclosures and panels

- Control and Protection

- Lighting

-

Products for exterior installations

- Products for worksite installations

- Products for tunnels

- Explosion-proof products (ATEX)

-

Other Marine Products for Ports, Camping and caravan parks (UNAV)

-

Plugs and sockets (UNAV)

-

Interlocked outlet (UNAV)

-

Connection systems for containers (Lloyd’s)

-

Junction boxes for marine use (UNAV)

-

Control devices and optical signals for marine use (UNAV)

-

Bells, sirens and horns for marine use (UNAV)

-

Lighting fixtures for marine use (UNAV)

-

Distribution turrets for water and electric

-

Fire prevention turrets

-

Plugs and sockets (UNAV)

- Professional electrical tools Cembre

- Access Control & Security Systems

- Explosion-proof products

- Bus (Dupline - Smart House / Building)

- Industrial Networks

- Power factor correction

- Photovoltaics (PV instalations)

- E-mobility

- Stainless Steel lighting systems STRAL

- Omniflow - Smart Cities Solutions

ATR421, Προγραμματιζόμενος ελεγκτής, Programmable controller

Programmable controller 15 cycles / 45 steps, 48x96mm. PIXSYS

Product Inquiry

Product Inquiry

DETAILED DESCRIPTION

ATR421

Programmer 48x96mm (1/8 DIN), single control loop. Allows the programming of 15 cycles/programs that can provide up to 45 steps/segments, all of which can be configured by the user as raise/maintain/lower. Programming mode of the work cycle that is intuitive and simple to use even for inexpert operators.

Step end wait software functions (in case of a delay of the process on the programmed setpoint value) and Cycle Recovery mode (after a power cut-off) are the main features of this programmer that has been specifically designed for the automation of industrial kilns, climatic chambers, dryers and the management of thermal processes in general that require the programming of cycles/curves with control of the process variable in relation to time.

Universal input and outputs that can be set as control, alarm/auxiliary analogue retransmission and/or serial RS485. All options can be configured from the keypad without selecting external Jumpers. Useful power supply range from 24 to 230V AC/DC with galvanic isolation from the power supply and between inputs and outputs.

MEMORY-CARD or parameter setting software help the installer configure the device quickly and easily and LABSOFTVIEW records trends.

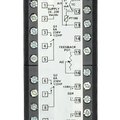

Specifications

- Dimensions: 48 x 96 (front panel) x 123 mm

- Power supply: 24...230Vac/dc ±15% 5

- Display: 4 digits 0,4" green + 4 digits 0,3" red

- Operating conditions: Temperature 0-45 °C, humidity 35..95 RU% (non condensing)

- Sealing protection: IP65 (Front panel) , IP20 (Box and Terminal bloks)

- Quick set-up options: Memory Card with / without battery, software LABSOFTVIEW

- Inputs: 1 x configurable (TC, K, J, S, R, PT100,PT500, PT1000, Ni100, PTC1K, NTC10K (B 3435K), 0/4..20 mA, 0..10 V), 1 χ digital input (1...9 cycle selection, Hold, Run, "Open door" lock), 1 x potentiometer input (Position signal by potentiometer for servo-valves / motorized-valves)

- Outputs: 2...4 x Relays, 1 x 1 SSR24, 1 x AnalogueSelection ( 4...20 mA or 0...10 Vdc for command or retransmission PV/SPV)

- Serial communication: RS485 Modbus RTU - Slave

- Software features: Control algorithms (ON - OFF with hysteresis, P., P.I., P.I.D., P.D. time-proportioned)

- Tuning: manual or automatic

- Data protection: Lock of control / alarm setpoint, Access to parameters by password

- Alarm modes: Absolute / Threshold, band, High / Low deviation, timed auxiliary programmable for single steps

- Gas mode: Open / Close logic for motorize valves, management of burners and fan, GID selection (management of burners during falling steps)

- Waiting function: Special function to compensate differences SPV / PV in case of overloaded system

- Cycle recovery: Resume the cycle after unexpected power failure

- Setpoint controller mode: Regulation on a fixed setpoint (function might be enabled from general menu or during a cycle in progress)

- Delayed start: Cycle start delayed by decremental timer

Ordering codes

- ATR421-14ABC1: Analogue input + 1 digital input + 4 Relays + 1 digital PNP / Alim. 24..230V AC/DC

- ATR421-12ABC-T1: Analogue input + 2 Relays + 1 digital PNP + 1 Analogue 0/4..20mA / 0..10V + RS485 / Alim. 24..230V AC/DC