- Wago Products

- Cabur Products

-

Cembre Products

-

Tube terminals - End sleeves

-

Ring - Fork - Pin - Blade terminals

-

Slide cable lug

-

Tube connectors

-

Copper tube crimp lugs

-

Copper single-hole terminal lug for circuit beakers

-

Crimping through/sleeve connectors

-

Aluminum tube crimp lugs

-

Bimetallic tube crimp lugs

-

Terminals in roll

-

Connections for for railway applications

-

Other products Cembre

-

Tube terminals - End sleeves

- Identification and labeling systems

-

Controls

- Pushbuttons - Selectors - Pilot lights

- Limit switches

- Timers

- Counters - Tachometers

- Digital meters-PID Control-Transducer-Converters

-

Monitoring relays

-

1-ph AC/DC voltage monitoring

-

Speed monitor relay

-

3-ph voltage monitoring

-

1-ph current monitoring

-

3-ph current monitoring

-

3-ph monitoring, phase loss-sequence, asymmetry etc

-

Frequency monitoring

-

Power monitoring

-

Power factor monitoring

-

Level control

-

Dry running and pump alternating

-

Motor temperature monitoring

-

Motor monitoring and potection units

-

Temperature - Humidity - CO2

-

Wind

-

1-ph AC/DC voltage monitoring

- Current transformers

-

Earth leakage control

-

Flush mounting earth leakage controllers

-

Internal mounting earth leakage controllers

-

DIN rail mounting earth leakage controllers

-

Earth leakage controllers with incorporated CT

-

Solid-core toroidal current transformers

-

Split-core toroidal current transformers

-

External multiplier for earth leakage controllers

-

Flush mounting earth leakage controllers

- Switching power supplies and Automatic battery chargers

- Surge protection devices

- PLC - Operator panels - Automation units

- Safety modules

-

Automatic transfer switches controllers

- Engine and generator controllers

- Software and applications

-

Sensors

- Temperature

-

Humidity

-

Pressure transmitters

-

Inductive

-

AC - cylindrical - 2 wires

-

AC - DC - AC/DC - rectangular

-

DC - cylindrical - 2 wires

-

DC - cylindrical - 3 wires

-

DC - for cleaning processes with high pressure and temperature - Ecolab

-

DC - for high temperature

-

Special applications (metal face, analog e.t.c.)

-

Namur and amplifiers

-

Presence and direction of vehicles

-

AC - cylindrical - 2 wires

- Magnetic

- Capacitive

-

Photoelectric

-

Diffuse reflective

-

Diffuse reflective Background suppression

-

Retro-reflective

-

Retro-reflective, Polarized

-

For transparent objects

-

Through-beam

-

Through-beam controllers and sensors

-

Color contrast and color points

-

LASER (narrow beam)

-

Fork Sensor

-

Domestic garage door & Industrial gates control

-

Non conductive liquid level sensor

-

Fibre Optic

-

Diffuse reflective

- Ultrasonic

- Connectors and Cable Plugs

- Level control

- Loop detectors

- Environmental (exterior use)

- Air quality (interior use)

-

Motion - Presence detector - Radar

-

Switches

- Plug-in industrial relays

-

Power and auxiliary contactors - Thermal overload relays

- Motor protection circuit breakers

-

Solid state relays

-

Single phase, small dimensions

-

1 pole solid state relays without built in heatsink

-

1 pole solid state relays with built in heatsink

-

With 2 or 3 independent or not switching poles

-

For DC loads

-

With soft start and analog functions

-

Special functions: sensing, communication, protection

-

3 pole solid state relays with built in heatsink

-

3 phases solid state relays without built in heatsink

-

Electronic contactors and reversing contactors

-

Hybrid single and 3-phase solid state relays

-

Heatsink and accessories

-

Single phase, small dimensions

- Soft starters

- Frequency drivers / inverters

-

Motor control and protection Units

- Switch disconnectors and Rotary cam switches

- Miniature circuit breakers - Fuse holders - Residual current operated circuit breakers

-

Automatic transfer switches

- Energy management

-

Installation and Marine products

- Industrial Plugs and sockets

- Interlocked socket outlets

- Enclosures and panels

- Control and Protection

- Lighting

-

Products for exterior installations

- Products for worksite installations

- Products for tunnels

- Explosion-proof products (ATEX)

-

Other Marine Products for Ports, Camping and caravan parks (UNAV)

-

Plugs and sockets (UNAV)

-

Interlocked outlet (UNAV)

-

Connection systems for containers (Lloyd’s)

-

Junction boxes for marine use (UNAV)

-

Control devices and optical signals for marine use (UNAV)

-

Bells, sirens and horns for marine use (UNAV)

-

Lighting fixtures for marine use (UNAV)

-

Distribution turrets for water and electric

-

Fire prevention turrets

-

Plugs and sockets (UNAV)

- Professional electrical tools Cembre

- Access Control & Security Systems

- Explosion-proof products

- Bus (Dupline - Smart House / Building)

- Industrial Networks

- Power factor correction

- Photovoltaics (PV instalations)

- E-mobility

- Stainless Steel lighting systems STRAL

- Omniflow - Smart Cities Solutions

Laser, foreground suppression, LD30CPBR,LD30EPBR

Smart IO-Link Laser photocells for detailed applications. Adjustable background / foreground suppression. Carlo Gavazzi

Product Inquiry

Product Inquiry

DETAILED DESCRIPTION

The LD30CPBR10BP..ΙΟ (plastic models) & LD30EPBR60BP..ΙΟ (metal models) are a part of the latest generation of high-performance Photoelectric Laser sensors designed to solve hallenging detection tasks due to Laser, Background Suppression, Foreground Suppression and Dual Detection features. The small light spot makes detection very precise.

Especially the LD30EPBR10BPxxIO stainless steel sensors are manufactured with high-quality materials designed for harsh environments.

They are intended for use in environments where high-pressure cleaning (IP69K), cleaning agents and disinfectants are used daily, thanks to their ECOLAB approval.

The strong stainless steel (AISI316L) together with high-quality plastic materials like PMMA and PES sealings of FKM ensure a safe and excellent mechanical resistance.

The compact sensor design is ideally suited to confined spaces.

Features

Rated operational voltage (UB) 10 ... 30 VDC

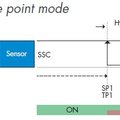

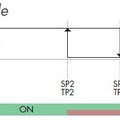

Input selector: Channel A and Channel B: Deactivated, SSC1, SSC2, Dust alarm 1, Dust alarm 2, Temperature alarm, External input, Application functions. Factory settings: SSC1

Logic functions: Channel A + B for SO1 and SO2: Direct, AND, OR, X-OR, SR-FF. Factory settings: Direct

Timer mode for SO1 and SO2: Disabled, ON delay, OFF delay, ON delay and OFF delay, One-shot leading edge, One-shot trailing edge. Factory settings: Disabled

Timer scale for SO1 and SO2: ms, s, min. Factory settings: ms

Timer value for SO1 and SO2: 0 ... 32 767. Factory settings: 0

Sensor output for SO1 Pin 4 Black wire: Disabled output, NPN, PNP, Push-Pull. Factory settings: PNP

Sensor output for SO2 Pin 2 White wire: Disabled output, NPN, PNP, Push-Pull, External input, active high, External input, active low, External teach (Teach-in). Factory settings: PNP

Output Inverter for SO1 Pin 4 Black wire: N.O., N.C. Factory settings: N.O.

Output Inverter for SO2 Pin 2 White wire: N.O., N.C. Factory settings: N.C.

Ηousing: Plastic (IP67) or Stainless Steel (IP67, P68, IP69K, ECOLAB)

Applications

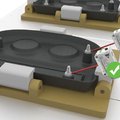

Detecting of transparent or translucent plastic bottles.

The detection distance is almost independent of the colour of the object to detect.

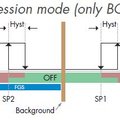

Dual Detection: A dual detection sensor works as a foreground suppression sensor combined with a diffuse reflective sensor. This sensing principle evaluates both the position change as well as the light intensity of the received light. This allow detection of eg. transparant PET bottles.

Pattern Recognition: An easy way to verify that a product is manufactured to the specification e.g. Furniture production where tabs or holes has to be with a defined pattern.

Speed and Length: Monitor the speed and length of an object on a conveyour for e.g. sorting on size.

Divider function: A de-central counting function that gives a signal when a preset count level is reached e.g. when a certain amount of items are packed in a carton box it ask for a new box.

Object and Gap Monitoring: Function that can sort out good objects and gaps between them so e.g. a packaging machine only receive objects with the correct size and gaps.

Main functions

• The detection distance is almost independent of the colour of the object to detect.

• The sensor can be operated in IO-Link mode once connected to an IO-Link master or in standard I/O mode.

• Measured sensing distance as process data.

• Neighbour interference protection.

• Sensing distance by teach-button, teach by wire or by IO-link parameter.

• Quality of Run and Quality of Teach result.

• Temperature data for preventive maintenance.

• Front-end check for preventive maintenance.

• Dual Detection